ISO 22000 is the food safety management system that replaced the ΕLΟΤ 1416 standard and HACCP (Hazard Analysis & Critical Control Points). Its aim is to ensure food safety, that is, to ensure that food products are not detrimental to consumers’ health. The system can be applied to food processing businesses of all sizes and types.

According to current Regulation 852/2004 of the European Parliament and the Commission that replaced Directive 93/43/EU, the application, maintenance and revision of a Food Safety Management System including Hazard Analysis and Critical Control Points (HACCP) is a requirement for companies that:

- Prepare

- Process

- Manufacture

- Package

- Store

- Transport

- Distribute

- Handle

- Offer for sale or supply of foodstuffsFirms include packers, manufacturers, restaurateurs, supermarkets, caterers, hotels that have mass food premises, etc.The benefits of the implementation and certification of a HACCP System are summarised as follows:

- The company’s reputation is improved thanks to its commitment to protect the health of its consumers

- The application of preventive measures leads to reduction of production costs because fewer batches of products are rejected

- The company acquires an important advantage in export activities against its competitors, as opportunities are created for penetration into international markets

- Proof of compliance to legislation is available to the competent authorities

- Proof is available on the company’s increased awareness and commitment to the protection of public health, and on its ability to produce healthy food

Because it is a recognised food safety management system, customers require it as product safety guarantee (more and more firms demand that suppliers are covered by a certified HACCP system).

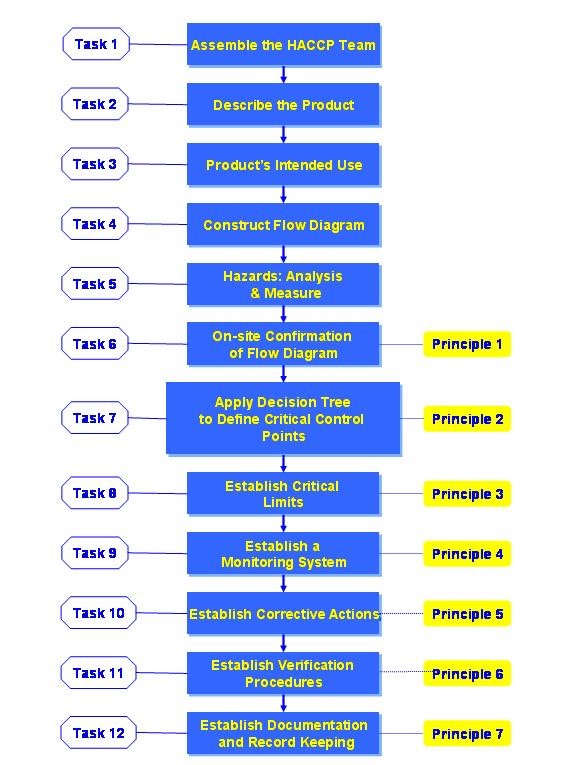

- The Tasks involved in the implementation of the HACCP system are those proposed by the Codex Alimentarius Committee and are presented in the figure that follows. The 7 Principles are required structural elements of the System:

- ISO 22000 is an integrated framework for Food Safety Management. When rules of Good Manufacturing Practices (GMP) and Good Health Practices (GHP) are introduced in the system applied, companies have an integrated food quality and safety management system.Competition, customer demands and the retailers’ need to have an internationally recognised food safety assurance and certification system, led to the establishment of GFSI (Global Food Safety Initiative). The three standards that satisfy GFSI requirements are BRC (British Retail Consortium), IFS (International Food Standard) and HACCP (Hazard Analysis & Critical Control Points).The IFS was developed by German and French retailers. The standard is a combination of ISO 9001:2000 and of HACCP with particular emphasis on the control of natural risks, associated mainly with packaging materials and food management. There are five basic chapters: Quality System Management, Management’s Responsibility, Resource Management, Product Creation, and Measurement, Analysis, and Improvement. The standard concerns, mainly, food suppliers, who are members of The French and German association of retailers and firms that standardise or package foods for large food-seller chains. The anticipated benefits for firms certified by IFS are: Cost Reduction, Competitiveness, Marketing, and Customer Satisfaction.

- The EUREPGAP standard is complementary and concerns quality assurance of foods coming from agricultural production with the use of Good Agricultural Practices. It covers the food’s itinerary from production in the farm, up to the point of its packaging, where BRC, IFS or HACCP, now ISO 22000, take over.

- Retail companies trading branded items may have their quality management system certified, according to the BRC system. This standard is a combination of ISO 9001:2000 and HACCP, with particular emphasis on the control of natural risks associated mainly with packaging materials and food management. The standard is divided into six chapters: HACCP System, Quality Management System, Buildings, Product Control, Process Control, and Personnel. Certification and offers companies assurance as regards supplier and customer satisfaction.

- In the filed of agricultural exploitations of any size, in particular, the AGRO 2-1 and 2-2 Integrated Management Systems (IMS) are applied. The aim is to assure product quality and safety, respecting the environment and using proper production procedure.